Finely engineered

for bone

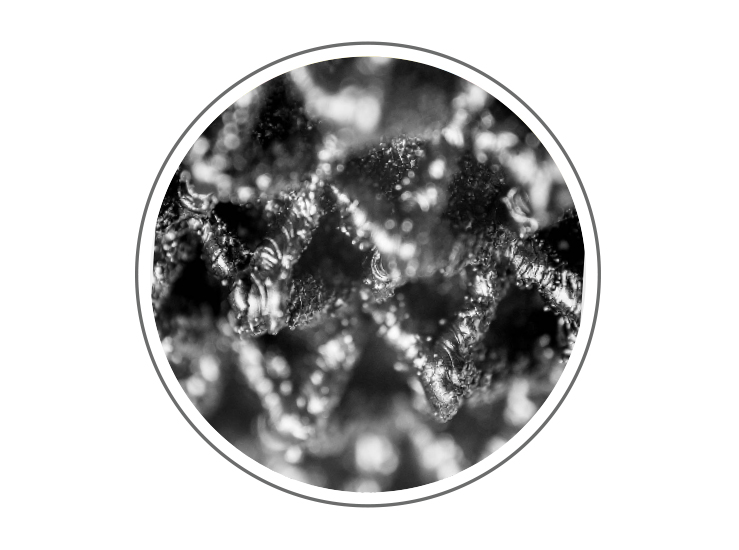

3D Metal is a state-of-the-art advanced biomaterial structure that is finely engineered for the bone. It is made of Titanium alloy (Ti6Al4V), and it is obtained by means of 3D printing technology, an innovative one-step layer-by-layer additive manufacturing process (not a coating). This advanced technology allows for designing engineered 3D structures starting from a CAD model in a precise, predictable and reproducible manner.

3D Metal can be particularly useful for optimizing implant performance, thus allowing for effectively managing challenging clinical scenarios:

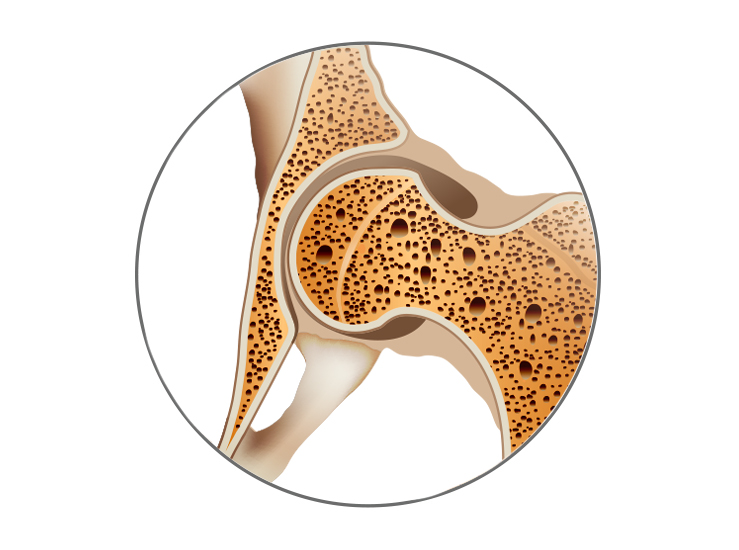

Patients with demanding bone conditions

Patients with demanding bone conditions Active patients

Active patients Cases of bone defects or bone loss

Cases of bone defects or bone loss Custom solutions

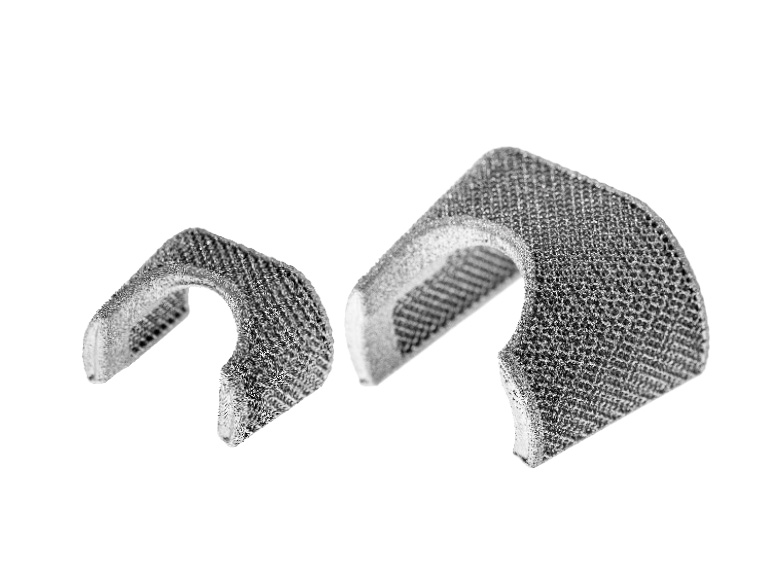

Custom solutions3D Metal implants are manufactured by means of 3D printing technology.

3D printing is an additive manufacturing production process which allows for obtaining devices starting from Titanium powder (Ti6Al4V).

The process uses an energy source to melt and fuse selected regions of a metal powder bed, according to a computer-aided design (CAD) model.[1] 3D printing allows for designing engineered 3D structures in a precise, predictable and reproducible manner.[1] This process allows for obtaining devices with complex structures, that could not be easily obtained through the common machining processes.

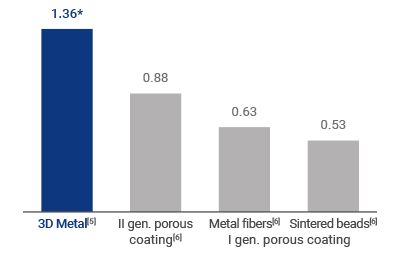

Primary stability is crucial for implant performance following a joint replacement procedure. 3D Metal implants are characterized by an outer surface with intrinsic high friction and scratch-fit to obtain superior primary stability.

A significant measure of the initial stability is the coefficient of friction.[4]

Friction coefficient: 1.36*[5]

* Tests performed on the reinforced pyramid structure.

Specific parameters of the 3D Metal porous structure can be designed and controlled, such as pore size and porosity. These two parameters are crucial to obtaining an efficient biological fixation.[4]

Cells grow on the device’s outer surface only.

Cells penetrate the 3D structure. The more pores are interconnected, the more cell penetration is effective.

| Pore size | Porosity | |||

|---|---|---|---|---|

| For effective bone in-growth[7] | 100 - 1000µm | 50 - 90% | ||

| 3D Metal | 450 - 900µm* | 65 - 80%* | ||

*depending on specific net structure and device analyzed region

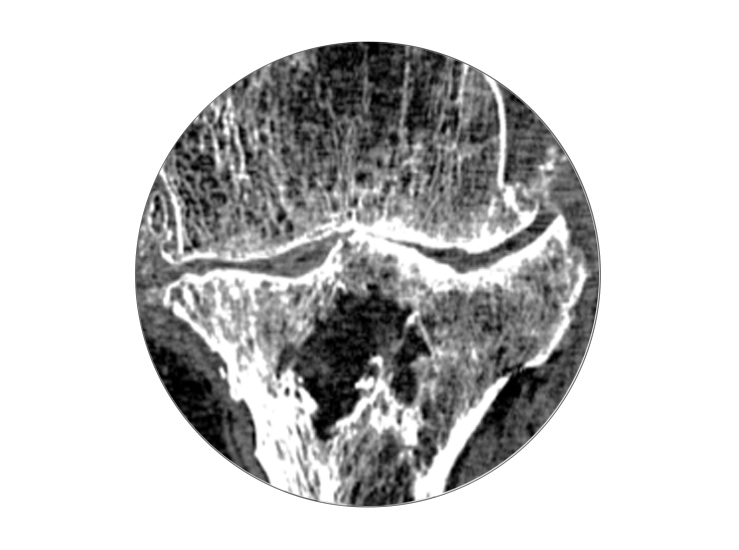

The efficient connection with the bone of the 3D Metal structures has been validated by means of an animal study in young sheep.[5]

Histological analysis (both from cortical and cancellous sites) showed both on-growth and in-growth starting from the first time-point (4 weeks) with lack of any fibrous tissue, demonstrating an early and effective bone integration.

Mechanical parameters at the 3D Metal samples-bone interface during the extraction phase were recorded. The performed mechanical tests showed a strong sample connection to the bone already at 4 weeks, further increasing at 12 weeks after implantation.

Sample topographical characterization has been performed through optical microscopy and SEM. Precision and reproducibility are clear in the registered images for both pyramid and honeycomb structures.

By means of a SINGLE technology it is possible to design and manufacture different advanced net structures which, applied to different products across the entire Medacta’s joint replacement portfolio, allow the surgeon to effectively face most clinical cases (from standard primary to complex revision surgeries).

Mpact 3D Metal Two-hole

Hemispherical two hole cup

Mpact 3D Metal Multi-hole

Hemispherical multi hole cup

Augments 3D metal

Acetabular bone defect filling devices

Mpact 3D Metal Monocer

Monoblock cup with built-in ceramic liner

3D Metal B-Cage

Antiprotrusio cage

Iliac Screw Mpact 3D Metal

Iliac fixation acetabular cup

3D Metal Femoral Cones

Femoral bone defect filling devices

3D Metal Tibial Cones

Tibial bone defect filling devices

Medacta Shoulder System

Stemless Humeral Metaphysis

MyImplant

Custom-made solutions

Please verify approval of the devices described in this document with your local Medacta representative.

[1] L. Dall’Ava, H. Hothi, A. Di Laura, J. Henckel, A. Hart. 3D Printed Acetabular Cups for Total Hip Arthroplasty: A Review Article. Metals 2019, 9, 729.

[2] T. McTighe, D. Brazil, W. Bruce. Metallic Alloys in Total Hip Arthroplasty. In The Hip: Preservation, Replacement and Revision; J. Parvizi, N. Goyal, J. Cashman; Data Trace Publishing Company: Brooklandville, MD, USA, 2015; pp. 1–12. ISBN 9781574001495.

[3] M. Long, H.J. Rack. Titanium alloys in total joint replacement—A materials science perspective. Biomaterials 1998, 19, 1621–1639.

[4] T. R. Shultz, J. D. Blaha, T. A. Gruen, T. L. Norman. Cortical Bone Viscoelasticity and Fixation Strength of Press-Fit Femoral Stems: A Finite Element Model. Journal of Biomechanical Engineering 2006; 128: 7-12

[5] Medacta: data on file

[6] B. Levine. A New Era in Porous Metals: Applications in Orthopaedics. Advanced Engineering Materials 2008; 10, No. 9

[7] L. Dall’Ava, H. Hothi, J. Henckel, A. Di Laura, P. Shearing, A. Hart. Comparative analysis of current 3D printed acetabular titanium implants. 3D Printing in Medicine 2019; 5:15