.svg)

Hemispherical Cementless

Cup System

As part of the comprehensive Mpact System, Mpact 3D Metal Monocer is Medacta’s hemispherical cementless monoblock cup, featuring a 3D-printed shell with a built-in ceramic liner.

The optimized ceramic liner design offers an improved shell-to-head ratio, allowing for the use of large-diameter heads with a low-wear ceramic-on-ceramic bearing surface. This type of systems provides an increased range of motion and enhanced stability[1], making the Mpact 3D Metal Monocer cup an ideal solution for promoting the restoration of an active lifestyle in patients.

Mpact 3D Metal Monocer features a 3D-printed shell with a high-friction porous structure, providing effective treatment for demanding patients while promoting both primary stability and secondary fixation.

The Mpact 3D Metal Monocer cup features a 10 mm shell-to-head clearance, allowing it to be paired with large ceramic femoral heads. Larger diameter heads provide enhanced stability[1] by increasing the jumping distance and offering a greater range of motion compared to the articulation of conventional small diameter heads. This leads to improved functionality and stability[1], while also reducing the risk of dislocation.

Mpact 3D Metal Monocer combines advanced materials and manufacturing technologies. The 3D Metal Monocer shell features an advanced biomaterial structure that is finely engineered for the bone. It is made from a titanium alloy (Ti6Al4V) and produced using 3D printing technology.

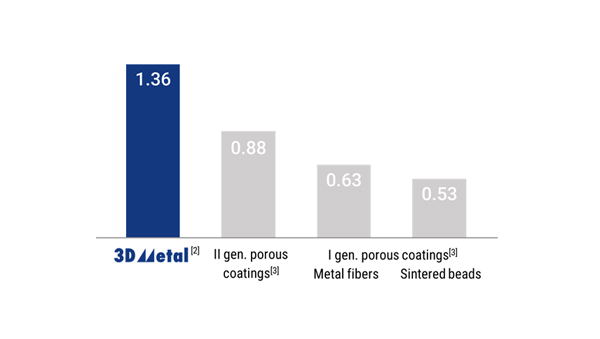

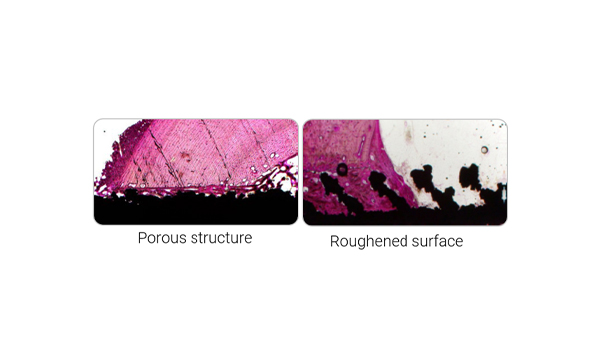

3D Metal enables the design and manufacture of implants with a high coefficient of friction (μ), enhancing grip at the bone interface and providing superior primary stability[3,4]. Additionally, key parameters of the 3D Metal’s porous structure, such as pore size and porosity, can be precisely designed and controlled. These factors are essential for achieving an efficient biological fixation[5]. The efficient connection with the bone has been validated through an animal study[4].

Significantly higher friction coefficient than the competitors’ solutions

Cells penetrate the 3D structure.

The more pores are interconnected, the more cell penetration is effective.

Mpact 3D Metal Monocer features a built-in ceramic liner. The shell/liner assembly is performed in a white chamber through a proprietary in-house process*, which involves a hydraulic press capable of applying a precisely controlled force.

The pre-assembled ceramic liner has the advantage of avoiding intraoperative shell/liner misalignment and assembling-related issues.

*The pressing process is actively monitored and adjusted to maintain a specific force level, ensuring precise and consistent assembly results

.png)

- 18 sizes (from Ø42 to Ø66)

- Different head options (Ø44 and Ø48) for bigger shell sizes

Materials:

• 3D Metal Ti-6Al-4V outer shell

• Al2O3-ZrO2 inner pre-assembled liner

MectaCer BIOLOX delta Ceramic Heads

Material:

• BIOLOX® Delta Al2O3-ZrO2

MectaCer BIOLOX Option System

Materials:

• Head BIOLOX® Delta Al2O3-ZrO2

• Sleeve: Ti-6Al-4V (ISO 5832-3

Mpact 3D Metal Monocer is part of the Mpact System, a comprehensive hemispherical cup platform featuring different shell and liner designs and materials, allowing for efficiently treating the majority of the clinical cases from primary to revision surgeries, according to patients’ needs.

The Medacta offering embraces a Personalized Medicine Vision with a comprehensive platform for a personalized care experience with a Holistic Approach. Innovative implants, minimally invasive surgical techniques and technologies bring value throughout the entire patient journey.

[1] Cooper HJ, Della Valle CJ. Large diameter femoral heads. Bone Joint J. 2014;96-B(11_Supple_A):23-26. doi:10.1302/0301-620X.96B11.34342.

[2] Australian Orthopaedic Association National Joint

Replacement Registry – Automated Industry Report 15755, Medacta Australia, Mpact Total Conventional Hip - Report Generated: 27 August 2024, Data Period: 1 September 1999 - 26 August 2024.

[3] T. R. Shultz, J. D. Blaha, T. A. Gruen, T. L. Norman. Cortical Bone Viscoelasticity and Fixation Strength of Press-Fit Femoral Stems: A Finite Element Model. Journal of Biomechanical Engineering 2006; 128: 7-12.

[4] Medacta: Data on file. [5] L. Dall’Ava, H. Hothi, A. Di Laura, J. Henckel, A. Hart. 3D Printed Acetabular Cups for Total Hip Arthroplasty: A Review Article. Metals 2019, 9, 729.